YUNG CHI RUBBER was established in 1988. With over three decades of expertise in the rubber sealing industry, we provide high-quality, customized sealing solutions for a wide range of sectors including automotive, sports equipment, machinery manufacturing, electronics, hardware, and semiconductors—supported by modern production facilities and a professional technical team.

At our core lies stringent quality control and continuous technological innovation. Our products comply with multiple international certifications, ensuring outstanding durability, sealing performance, and environmental adaptability, keeping us at the forefront of the industry.

YUNG CHI RUBBER upholds the principle of "Quality First, Customer Foremost." We have established solid partnerships with numerous renowned enterprises worldwide and integrate ESG principles into our core strategy. Committed to green innovation, we provide efficient sealing solutions that meet international environmental standards, significantly reduce the carbon footprint of products, and support customers in achieving their sustainability transitions. Together, we strive toward environmental sustainability and excellence in corporate governance.

YUNG CHI RUBBER delivers tailored, efficient, and sustainable sealing solutions, helping you build more competitive and environmentally responsible products.

• Grinding machine

• CNC milling machines

• Dispersion Kneader

• Rubber mixing mill

• Cutting Machine

• Vaciim Vulcanizer

• Convection Cabinet Ovens

• High-Speed Deflashing Machine

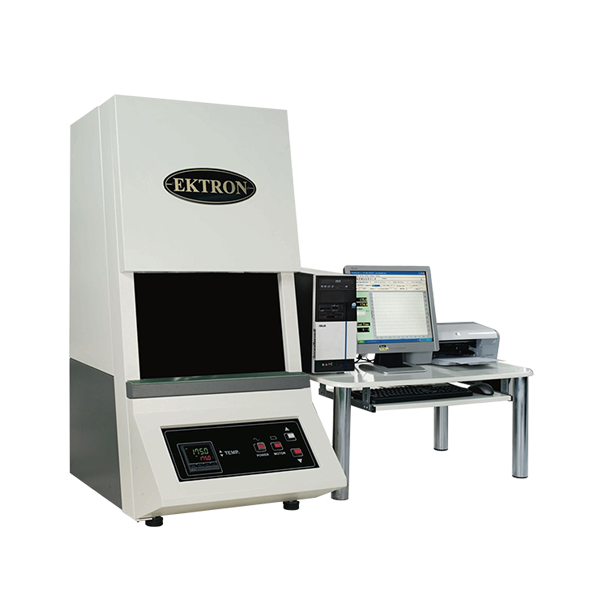

• Curing Curves

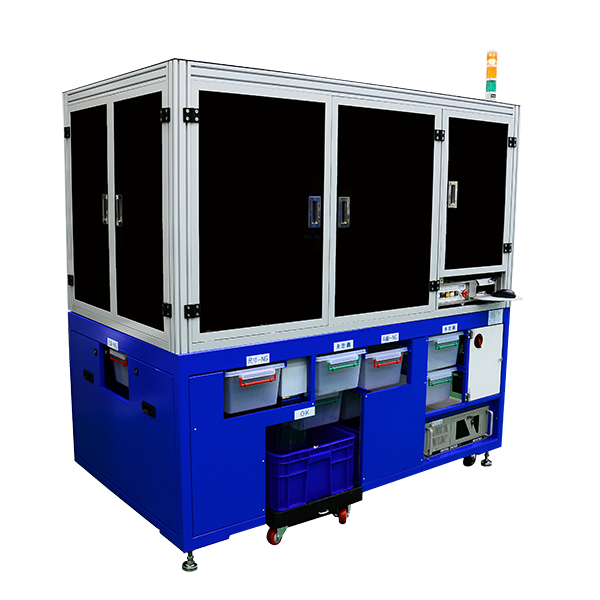

• Automated Optical inspection

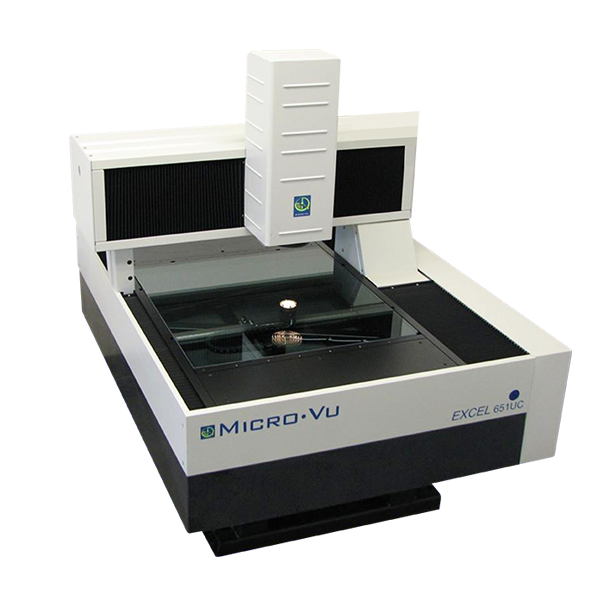

• Mirco-Vu 3D Vision Measure

• UPT machine for dimensional control

• hardness tester

We use cookies to provide the services and features offered on our website, and to improve our user experience. By using this website, you consent to the use of cookies.